All Major Equipment Received for HPQ Fumed Silica Reactor Pilot Plant

Final Assembly on Track for Q2 2024 Commissioning

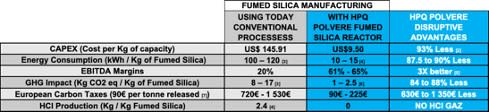

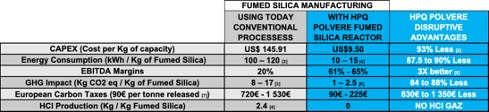

HPQ Fumed Silica - Table

MONTREAL, March 12, 2024 (GLOBE NEWSWIRE) -- HPQ Silicon Inc. (“HPQ” or the “Company”) (TSX-V: HPQ) (OTCQB: HPQFF) (FRA: O08), a technology company specializing in green engineering of silica and silicon-based materials, is pleased to update shareholders on the advancement of its Fumed Silica Reactor (FSR) Pilot Plant project.

Further to our February 6th, 2024 release, HPQ Silicon’s wholly owned subsidiary, HPQ Silica Polvere Inc. (HPQ Polvere), received notification from its technology provider and equipment supplier, PyroGenesis Canada Inc. (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY) (PyroGenesis), that all the materials needed for the Fumed Silica Reactor (FSR) Pilot Plant project have been received.

HPQ’S FUMED SILICA REACTOR PILOT PROJECT: VALIDATING COMMERCIAL POTENTIAL OF THE TECH

Now that all major equipment’s needed have been received, the 50 tonnes per year (TPY) FSR pilot plant now moves to the final fabrication and assembly phase; with a scheduled commissioning in Q2 2024.

“Having successfully achieved the following key milestones:

Made commercial grade Fume Silica directly from quartz at lab scale using HPQ FSR technology (May 17th, 2023, release),

Attracted the interest of major industry players that signed 3 party NDA’S [1] to test our material characteristics (May 25th, 2023, August 24th, 2023, September 14th, 2023, and October 18th, 2023, releases),

Received independent third-party confirmation that we made commercial grade Fume Silica directly from quartz at lab scale using HPQ FRS technology (November 8, 2023, release),

Completed an internal technical and economic study that indicated HPQ FSR’s robust potential at commercial scale (January 10th, 2024, release) and

Attracted the interest of an industrial group to explore the potential of creating a commercial FSR 1,000 TPT plant joint venture (January 31st, 2024, release).

We are about to start the most exciting part of the project, validating, at a pilot plant scale, our substantial, unique, and proprietary advantages, the ability to manufacture commercial-grade Fumed Silica directly from quartz in one step for significantly less than all traditional manufacturers,” stated Mr. Bernard Tourillon, President and CEO. “With commissioning scheduled to commence in Q2 2024, the time for third parties showing strong interest in our tech to stay on the sideline is getting shorter.”

A RECAP OF HPQ POLVERE'S DISRUPTIVE ADVANTAGES

The table below clearly illustrates the numerous disruptive advantages of HPQ Polvere's Fumed Silica Reactor (FSR) compared to traditional Fumed Silica Manufacturing.

Table 1) HPQ Polvere's FSR compared to traditional Fumed Silica Manufacturing.

"In emphasizing the significance of the upcoming pilot plant phase,” Mr. Tourillon expressed, “One of the additional advantages is that we fully expect to further validate these numbers and improve them. This underscores our commitment to ongoing refinement and optimization as we move forward in the project.”

THE PILOT PLANT

The construction of the FSR pilot plant is set to take place in a dedicated space within PyroGenesis’ facilities, featuring tailor-made infrastructure to address the pilot plant’s distinctive ventilation, safety, and access needs. An allocated 4,000 sq ft facility, with a height allowance of 30 feet, has been designated to accommodate the pilot plant, which boasts an approximate layout footprint of 50ft by 30ft.

“We are rapidly moving forward with the fumed silica reactor pilot plant construction, as we recognize that numerous industries will benefit from what we believe is a truly innovative approach to producing one of the most in-demand materials”, said Mr. P. Peter Pascali, CEO and President of PyroGenesis. “Conventional fumed silica processes, which rely on silicon metal (Si) as raw material, not only have a significant carbon footprint of around 9.5 tonnes of CO2 equivalent per tonne of fumed silica, but also present complex process challenges which include, but are not limited to, using hazardous materials.[8] The technology developed by PyroGenesis for HPQ Polvere is designed to offer significant economic and environmental advantages over conventional manufacturers – improving profitability, but also reducing the environmental footprint and reducing the harmful chemicals associated with traditional fumed silica production.”

REFERENCE SOURCES

[1] |

| PyroGenesis participation in the NDA agreements is done at HPQ's express request. |

[2] |

| Traditional Fumed Silica manufacturing involves a complex three-step process. Step 1: Conversion of Quartz to Silicon Metal (Si), with an average Capex of around US$9.38 per kilogram of annual capacity (for reference, the PCC BakkiSilicon Plant in Iceland cost US$300 million for an annual capacity of 32,000 tonnes). Step 2: Conversion of Si to Silicon Tetrachloride (SiCl4), with an average Capex of approximately US$125.00 per kilogram of annual capacity (e.g., Wacker Chemie AG Polysilicon's US production plant cost US$2.5 billion for an annual capacity of 20,000 tonnes). Step 3: Burning Silicon Tetrachloride (SiCl4) with Hydrogen and Oxygen to produce Fumed Silica (SiO2), incurring an average Capex of around US$11.54 per kilogram of annual capacity (Wacker Chemie AG's US Fumed Silica plant cost US$150 million for an annual capacity of 20,000 tonnes). The combined Capex for these three steps averages at US$145.92 per kilogram of annual capacity. According to a rough order of magnitude study by PyroGenesis, our one-step process for making Fumed Silica is estimated to have an average Capex per kilogram of annual capacity between US$9.00 and US$10.00, which is approximately 93% less than traditional processes. |

[3] |

| Frischknecht, Rolf, et al. "Life cycle inventories and life cycle assessment of photovoltaic systems." International Energy Agency (IEA) PVPS Task 12 (2020). |

[4] |

| PyroGenesis Canada Inc. |

[5] |

| Average EBITDA margins of 20% are derived from two sources, with Link #1 leading to Source #1 and Link #2 leading to Source #2 (Specialty Additives division). Management has calculated the EBITDA margins for the Fumed Silica Reactor (FSR) based on data derived from third party sources and publicly available information. These figures will be updated upon completion of the pilot testing phase. The 5% range in HPQ Polvere's EBITDA margins considers PyroGenesis' option to convert its 10% royalties into a 50% ownership stake in HPQ Polvere's remaining equity. |

[6] |

| The 1 Kg eq of CO2 per Kg of Fumed Silica is based on Hydro Quebec data that indicate in Quebec 1.3 g of CO2 are generated eq per KWh. While the 2.5 is based on the Canadian average for electricity generation carbon intensity of 150 g per KWh. |

[7] |

| The Wall Street Journal article, April 18, 2023, “World’s First Carbon Import Tax Approved by EU Lawmakers” |

[8] |

| 2012 – Executive summary: “SILICON-CHEMISTRY CARBON BALANCE, AN ASSESSMENT OF GREENHOUSE GAS EMISSIONS AND REDUCTIONS”, Covering the Production, Use and End-of-Life of Silicones, Siloxanes and Silane Products in Europe, North America, and Japan. [Pages 20 to 21] (Commissioned by Global Silicones Council, Centre Européen des Silicones, Silicones Environmental, Health and Safety Council of North America Silicone Industry Association of Japan). |

| ||

About PyroGenesis Canada Inc.

PyroGenesis Canada Inc., a high-tech company, is a leader in the design, development, manufacture and commercialization of advanced plasma processes and sustainable solutions which reduce greenhouse gases (GHG) and are economically attractive alternatives to conventional “dirty” processes. PyroGenesis has created proprietary, patented, and advanced plasma technologies that are being vetted and adopted by multiple multibillion dollar industry leaders in three massive markets: iron ore pelletization, aluminum, waste management, and additive manufacturing. With a team of experienced engineers, scientists and technicians working out of its Montreal office, and its 3,800 m2 and 2,940 m2 R&D and manufacturing facilities, PyroGenesis maintains its competitive advantage by remaining at the forefront of technology development and commercialization. The operations are ISO 9001:2015 and AS9100D certified, having been ISO certified since 1997. For more information, please visit: www.pyrogenesis.com

About HPQ Silicon

HPQ Silicon Inc. (TSX-V: HPQ) is a Quebec-based TSX Venture Exchange Tier 1 Industrial Issuer.

HPQ is developing, with the support of world-class technology partners PyroGenesis Canada Inc. and NOVACIUM SAS, new green processes crucial to make the critical materials needed to reach net zero emissions.

HPQ activities are centred around the following four (4) pillars:

1) Becoming a green low-cost (Capex and Opex) manufacturer of Fumed Silica using the FUMED SILICA REACTOR, a proprietary technology owned by HPQ being developed for HPQ by PyroGenesis.

2) Becoming a producer of silicon-based anode materials for battery applications with the assistance of NOVACIUM SAS.

3) HPQ SILICON affiliate NOVACIUM SAS is developing a low carbon, chemical base on demand and high-pressure autonomous hydrogen production system.

4) Becoming a zero CO2 low-cost (Capex and Opex) producer of High Purity Silicon (2N+ to 4N) using our PUREVAP™ “Quartz Reduction Reactors” (QRR), a proprietary technology owned by HPQ being developed for HPQ by PyroGenesis.

For more information, please visit HPQ Silicon web site.

Disclaimers:

This press release contains certain forward-looking statements, including, without limitation, statements containing the words "may", "plan", "will", "estimate", "continue", "anticipate", "intend", "expect", "in the process" and other similar expressions which constitute "forward-looking information" within the meaning of applicable securities laws. Forward-looking statements reflect the Company's current expectation and assumptions and are subject to a number of risks and uncertainties that could cause actual results to differ materially from those anticipated. These forward-looking statements involve risks and uncertainties including, but not limited to, our expectations regarding the acceptance of our products by the market, our strategy to develop new products and enhance the capabilities of existing products, our strategy with respect to research and development, the impact of competitive products and pricing, new product development, and uncertainties related to the regulatory approval process. Such statements reflect the current views of the Company with respect to future events and are subject to certain risks and uncertainties and other risks detailed from time-to-time in the Company's ongoing filings with the security’s regulatory authorities, which filings can be found at www.sedar.com. Actual results, events, and performance may differ materially. Readers are cautioned not to place undue reliance on these forward-looking statements. The Company undertakes no obligation to publicly update or revise any forward-looking statements either as a result of new information, future events or otherwise, except as required by applicable securities laws.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

This News Release is available on the company's CEO Verified Discussion Forum, a moderated social media platform that enables civilized discussion and Q&A between Management and Shareholders.

Source: HPQ Silicon Inc.

For further information contact:

Bernard J. Tourillon, Chairman, President, and CEO Tel +1 (514) 846-3271

Patrick Levasseur, Director Tel: +1 (514) 262-9239

Email: Info@hpqsilicon.com

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/7693b887-665f-441e-976f-dd2d6b62770c