Plutonic and Trident Mineral Resource & Ore Reserve Update

Key Points

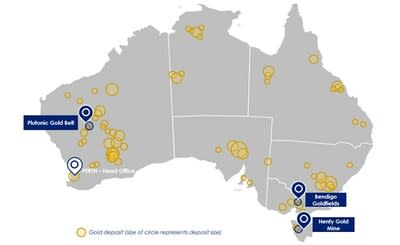

In June 2023, Catalyst acquired two companies to complete a consolidation of the Plutonic Gold Belt, a belt situated in northern WA

Previous owners of the belt had estimated Mineral Resources and Ore Reserves however, Catalyst felt a different estimation approach was needed

Since taking control, Catalyst has been undertaking this re-estimation process

These global Plutonic Resources include Resources for both the underground mine at Plutonic as well as the satellite development project, Trident

Mineral Resources and Ore Reserves for the Plutonic Main deposit are:

Indicated Resources: 17.2Mt at 2.9g/t Au for 1,592,000oz

Inferred Resources: 0.7Mt at 2.6g/t Au for 62,000oz

Reserves: 5.2Mt at 2.9g/t Au for 490,000oz

Resource and Reserve estimation has still not been undertaken by Catalyst on Plutonic East and the Hermes Area

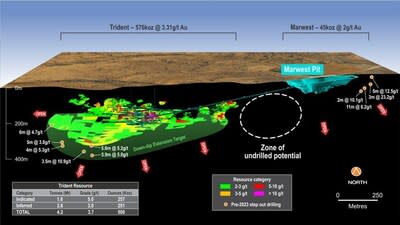

Mineral Resources for Trident are:

Indicated Resources: 1.6Mt at 5.0g/t Au for 257,000oz

Inferred Resources: 2.6Mt at 3.0g/t Au for 251,000oz

Trident resources have increased by 24% but grade has been reduced from the Vango estimates

Trident Definitive Feasibility Study is well progressed; Reserves expected to be released with this study in 2024

Release of this updated Mineral Resource estimate is an important step in Catalyst's process to rebuilding the foundations of the Plutonic Gold Belt. This release follows Catalyst's installation of a new operating team at the Plutonic gold mine. The combination of the two is responsible for the improved operating performance of the mine

PERTH, Australia, Dec. 6, 2023 /PRNewswire/ - Australian gold producer, Catalyst Metals Limited (Catalyst or the Company) (ASX: CYL) is pleased to provide an updated Mineral Resource & Ore Reserve statement for its Plutonic Gold Mine, and an updated Mineral Resource for the Trident deposit.

Importantly, the updates presented in this release relate to the Plutonic Main and Trident deposits only. The Plutonic Gold Belt hosts numerous open pit and underground deposits that have previously been estimated by other competent persons. Those deposits are yet to be re-estimated.

Catalyst's MD & CEO, James Champion de Crespigny, said: "We are pleased to have this important body of work behind us. Such estimates are the foundation of any operation. This update provides our team with the comfort to execute on the mine plan.

The updated Trident Resource estimate is different than expected. It now reflects what Catalyst believe is an improved approach to estimating such a deposit, updated drilling and a lower cut-off grade in this higher gold price environment. This Resource will form the basis of the pending Trident Definitive Feasibility Study.

That study is well progressed and the Company remains committed to its development as quickly as possible given its high grade and the latent mill capacity that currently exists at Plutonic.

Catalyst took control at Plutonic a little over five months ago and in that time there have been considerable changes. This is but another step in that transition plan as we set the company up for 2024."

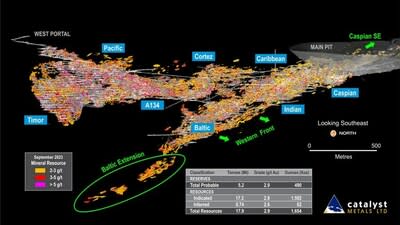

Plutonic Underground Mineral Resources

The Mineral Resource & Ore Reserve sit within the existing mining footprint and do not include virgin zones. Importantly, Table 1 below refers specifically to the Plutonic Main orebody and does not include any of the satellite deposits within the consolidated tenement package. The previously reported NI 43-101 Ore Reserves and Mineral Resources for the Plutonic Operations included satellite deposits such as Plutonic East, Plutonic West, Hermes and Perch. These remain NI 43-101 compliant, but not JORC compliant. Catalyst will review these estimates in due course.

The Mineral Resources and Ore Reserves for the Plutonic Underground Mine and Mineral Resources for the Trident deposit have been estimated for the first time by Catalyst following the acquisition of Superior Gold and Vango Mining.

Catalyst undertook a comprehensive re-estimation and classification of the entire Plutonic Main deposit Mineral Resources. This included the Plutonic Main underground and open pit areas. The previously reported Plutonic Main open pit Mineral Resources have now been incorporated into the Plutonic underground Mineral Resource inventory. Further work is planned to re-evaluate the Plutonic Main open pit potential.

The re-estimation and classification of the Plutonic Mineral Resources followed an extensive review of the geological and geostatistical behaviour of the Plutonic mineralisation together with mine production reconciliation. Catalyst has implemented a resource modelling technique that is well suited to estimating highly variable gold mineralisation. The modelling parameters were optimised so that the final Mineral Resource was well aligned with recent and historic production reconciliation performance.

The Mineral Resource Estimate (MRE) for Plutonic Underground has been undertaken with a focus on delineating areas of the MRE with Reaonable Prospects for Eventual Economic Extraction (RPEEE). Catalyst has applied a approach to historic mining depletion to ensure that the inclusion of potential 'un-mineable' remnants has been minimised. In addition, an underground Shape Optimiser (SO) evaluation has been applied to ensure that only cohesive groups of blocks that satisfy RPEEE are included in the MRE.

The previous combined Measured, Indicated and Inferred NI 43-101 MRE as at 31 December 2021 for the Plutonic Main underground and open pit contained 4.97Moz. Mine production depletion to 30 November 2023 accounts for 123Koz whilst changed modelling methodology, resource classification, historic depletion and RPEEE considerations has accounted for a reduction of 3.2Moz. A high proportion of the resource reduction is due to a grade reduction from 4.6g/t Au (Measured and Indicated) and 5.2g/t (Inferred) to the current 2.9g/t Au (and 2.6g/t Au for Inferred). Following is a summary of the Plutonic Underground Mineral Resources, as at 30 November 2023.

Table 1: Plutonic MRE (at 1.5g/t Au cut-off)

Classification | Tonnes (Mt) | Grade (g/t Au) | Ounces (Koz) |

Indicated | 17.2 | 2.9 | 1,592 |

Inferred | 0.74 | 2.6 | 62 |

Total | 17.9 | 2.9 | 1,654 |

Notes: | ||

1. | Mineral Resource estimated at 1.5g/t Au cut-off and reported within underground Shape Optimiser (SO). SO inputs include: | |

2. | Numbers may not add up due to rounding |

Plutonic Underground Ore Reserves

Following is a summary of the Plutonic Underground Ore Reserves, as at 01 January 2024.

Table 2: Plutonic Ore Reserves

Classification | Tonnes (Mt) | Grade (g/t Au) | Ounces (Koz) |

Probable | 5.2 | 2.9 | 490 |

Total | 5.2 | 2.9 | 490 |

Notes: | ||

1. | Ore Reserve estimated at 2.0g/t Au cut-off; | |

2. | Reserves are a combination of detailed mine design and Stope Optimised shapes. SO inputs include: Incremental Stoping and Grade Control Cost = AUD$60/t; Processing Costs = AUD$31/t ore; Site Administration Cost = AUD$23/t ore; Metallurgical Recovery = 84%; Royalties = 2.5%; Gold Price = AUD$2,600/oz; Minimum mining width = 3m, with a 1m dilution halo applied to Hangingwall and Footwall. | |

3. | Mining modifying factors of 10% dilution is applied to the in-situ stope tonnes, and ore recovery of 95% is applied. | |

4. | Numbers may not add up due to rounding |

As with the Mineral Resources, almost all of the reduction in ounces is due to a reduction of grade from 3.7g/t Au to 2.9g/t Au which is considered to be a more reliable estimate of mine grade going forward.

Trident Mineral Resources

The Trident deposit sits approximately 25km to the north-east of the Plutonic Gold Mine and the planned development in 2024 has been made possible by the recently completed consolidation of the Plutonic Gold Belt.

The estimation approach for the updated Trident MRE was primarily based on domains defined by geological, structural and mineralisation characteristics. This differs from the previous MRE approach where the continuity and volume of estimation domains were largely subjected to pseudo economic and mining criteria at an elevated cut-off grade. The Catalyst estimation approach has allowed the full grade-tonnage distribution of the mineralised domains, including additional lower grade material, to be incorporated into the MRE.

The Trident MRE has been undertaken with a focus on delineating areas of the MRE with Reasonable Prospects for Eventual Economic Extraction (RPEEE). An underground Shape Optimiser (SO) evaluation has been applied to ensure that only cohesive groups of blocks that satisfy RPEEE are included in the MRE.

In July 2023, Catalyst released a Scoping Study assuming an underground development at Trident, with ore transported and processed through the Plutonic mill (see ASX announcement entitled "Trident Scoping Study demonstrates Plutonic's potential" dated 19 July 2023). The Scoping Study utilised the previous Trident MRE (see ASX announcement entitled "Marymia Gold Project Mineral Resource – Updated" dated 22 February 2023). Catalyst considers that the updated MRE would result in changes to the results published in the Scoping Study. Updated results will be made available with the release of the DFS which is expected to occur in January 2024.

Following is a summary of the Trident Mineral Resource Estimate, as at 30 November 2023.

Table 3: Trident MRE

Deposit | Measured | Indicated | Inferred | Total | ||||||||

Tonnes | Grade | Ounces (koz) | Tonnes (Mt) | Grade | Ounces (koz) | Tonnes | Grade | Ounces (koz) | Tonnes | Grade | Ounces (koz) | |

Total | - | - | - | 1.6 | 5.0 | 257 | 2.6 | 3.0 | 251 | 4.2 | 3.7 | 508 |

Notes: | ||

1. | Mineral Resource reported within Shape Optimiser (SO) shapes at 2.0g/t Au cut-off. SO inputs include: | |

2. | Numbers may not add up due to rounding |

This announcement has been approved for release by the Board of Directors of Catalyst Metals Limited.

Competent person's statement

The information in this announcement that relates to Plutonic Mineral Resources has been compiled under the supervision of Mr Michael Millad and Mr Andrew Grieve. Mr Millad is a Director and Principal Geologist/Geostatistician at Cube Consulting Pty Ltd, and a Member of the Australian Institute of Geoscientists. Mr Grieve is a Principal Geologist at Cube Consulting Pty Ltd, and a Member of the Australian Institute of Geoscientists. Mr Millad and Mr Grieve have sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity that was undertaken to qualify as Competent Persons, as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The Joint Ore Reserves Committee Code – JORC 2012 Edition). Mr Millad and Mr Grieve consent to the inclusion in this report of the matters based on information in the form and context in which it appears.

The information in this report that relates to Ore Reserves is based on and fairly represents information and supporting documentation compiled by Cathy Barclay BEng (Mining Engineering), a Competent Person who is a Member of the Australasian Institute of Mining and Metallurgy. Cathy Barclay is a full-time employee of Catalyst Metals. She is a shareholder in Catalyst Metals and is entitled to participate in the Catalyst Performance Rights Plan. Cathy Barclay has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (JORC 2012).

Cathy Barclay consents to the inclusion in the report of the matters based on her information in the form and context in which they are presented. This Ore Reserve estimate has been compiled in accordance with the guidelines defined in the 2012 Edition of the Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (JORC 2012).

The information in this announcement that relates to Trident Mineral Resources has been compiled under the supervision of Mr Marcus Osiejak. Mr Osiejak is a Senior Resource Geologist at Cube Consulting Pty Ltd, and a Member of the Australasian Institute of Mining and Metallurgy . Mr Osiejak has sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity that was undertaken to qualify as a Competent Persons, as defined in the 2012 Edition of the 'Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves (The Joint Ore Reserves Committee Code – JORC 2012 Edition). Mr Osiejak consents to the inclusion in this report of the matters based on information in the form and context in which it appears.

JORC 2012 Mineral Resources and Reserves

Catalyst confirms that it is not aware of any new information or data that materially affects the information included in the original market announcements and that all material assumptions and technical parameters underpinning the estimates in the relevant market announcements continue to apply and have not materially changed. The Company confirms that the form and context in which the Competent Persons findings are presented have not been materially modified from the original market announcements.

ABOUT CATALYST METALS

Catalyst Metals is an ASX listed gold producer and explorer. Catalyst has a multi-asset strategy and controls three high grade, highly prospective and strategic gold belts in Australia:

In Western Australia, the Plutonic Gold Project, which holds the Plutonic Gold Mine and +40km of neighbouring, high-grade, underexplored tenements. The project hosts a JORC Indicated Mineral Resource of 1.6Moz at 2.9g/t Au and Inferred Mineral Resources of 0.06Moz at 2.6g/t Au.

In Victoria, a large, contiguous and dominant Four Eagles Gold Project, covering 75 kilometres of strike length immediately north of the proven +22Moz Bendigo goldfields and near Agnico Eagle's high grade Fosterville gold mine; and

In Tasmania, a strategic tenement package covering 25 kilometres of the under explored Henty fault and operates the high-grade Henty Gold Mine which has produced 1.4Moz of gold at a head grade of 8.9 g/t Au.

MINERAL RESOURCE ESTIMATE (Plutonic)

Cube Consulting Pty Ltd (Cube), was commissioned by Catalyst to prepare a Mineral Resource estimate (MRE) for the Plutonic Gold Mine (the Project), located in Western Australia.

Cube considered that data collection techniques are largely consistent with industry good practice and suitable for use in the preparation of a MRE to be reported in accordance with the JORC Code. Available quality control (QC) data supports use of the input data.

The Plutonic deposit comprises eight individual mine areas (Timor, Pacific, A134, Cortez, Caribbean, Caspian, Indian and Baltic).

A three-dimensional (3D) block model representing the mineralisation was created for each mine area using Leapfrog and Surpac software. Diamond core and underground face samples were used to interpolate gold grades into blocks. The grade estimation method combines Categorical Indicator Kriging (CIK) to define broad estimation domains, together with applying distance limiting at chosen grade thresholds to restrict the influence of the high grade and extreme grade values during grade interpolation. The block model was validated by visual checks, statistical comparisons, and swath plots to ensure that the block model was a good representation of the drillhole composite data.

The Mineral Resource is considered to have reasonable prospects for eventual economic extraction (RPEEE) given the access to critical infrastructure, the volume and grade of mineralisation available for mining and the RPEEE criteria which have been applied prior to reporting the Mineral Resource.

On Figure 1, the individual zones that comprise the Mineral Resources are presented in an isometric projection.

The following is a material information summary relating to the MRE, consistent with ASX Listing Rule 5.8.1 requirements. Further details are provided in JORC Table 1, which is included as Appendix A.

1. Geology and Geological Interpretation

The Plutonic gold deposit is located within the Archaean Plutonic Well Greenstone Belt, an elongate NE trending belt within the Marymia Inlier. The Marymia Inlier is an Archaean basement remnant within the Proterozoic Capricorn Orogen, and comprises two mineralised greenstone belts (Plutonic Well and Baumgarten greenstone belts), with surrounding granite and gneissic complexes. The Capricorn Orogen is situated between the Pilbara and Yilgarn cratons and is interpreted to be the result of the oblique collision of these two Archaean cratons in the early Proterozoic.

Gold mineralisation occurs in a large number of deposits and prospects in the Belt, with the main deposit at the Plutonic Gold Mine. Mineralisation regularly occurs as shallowly dipping, layer parallel lodes, although steep lodes and minor quartz-vein-hosted deposits also occur. Regionally within the greenstone belt, mineralised host rocks vary from amphibolites to ultramafics and banded iron formation (BIF). Lateritic and supergene enrichment are common throughout the Belt and has been mined locally. Biotite, arsenopyrite, and lesser pyrite/pyrrhotite are common minerals generally accepted to be associated with gold mineralisation.

Mineralisation at Plutonic Gold Mine is characterised by a series of steep to flat-lying, stacked replacement-style lodes, individually up to five metres wide that are hosted within ductile shear zones oriented slightly oblique to stratigraphy. Lodes are preferentially restricted within the top half of the Mine Mafic, which is a sequence of upper-greenschist to lower amphibolite grade basaltic flows of variable thickness sandwiched between the hanging wall and footwall ultramafic units. Lodes are characterised by intense banding, defined by crude mineral segregation and mineral alignment. Gold where visible, is commonly associated with grey quartz veins and fine-grained arsenopyrite and pyrrhotite.

The main style of gold mineralisation (Plutonic brown-lode) typically occurs as thin (~1 – 3 m wide) lodes that consist predominantly of quartz-biotite-amphibole-titanite-epidote-carbonate-tourmaline-arsenopyrite-pyrrhotite ± chalcopyrite ± scheelite ± gold. Visible gold is considered to have occurred at a late-stage during the evolution of the deposit as it is largely undeformed and overprints most, if not all, of the minerals and fabrics. It is typically associated with thin, discontinuous quartz-calc-silicate veins within the brown-lodes. Where these gold-bearing zones are well developed, they tend to be near-parallel to the stratigraphy as marked by the rare metasedimentary horizons and to the dominant foliation, which is also typically parallel to metasediment horizons. Geochemistry suggests that these lodes developed on the boundary between mafic units or are focused along or adjacent to minor metasedimentary units within the Mine Mafic unit. Lodes may be rich in arsenopyrite or pyrrhotite, and while arsenopyrite is a good indicator of mineralisation, it may not be present in all mineralisation.

2. Drilling Techniques

Over its 33-year production history, the Plutonic deposit has been sampled using numerous drilling and sampling techniques by Catalyst Metals Limited and previous operators. Drilling and sampling techniques by previous operators is assumed to be to industry standard at that time.

The sampling database has been compiled from information collected when the Project was under ownership of numerous companies including (listed from most recent):

Catalyst Metals (2023 to current)

Superior Gold (2016 to 2023)

Northern Star (2014 to 2016)

Barrick Gold (2001 to 2014)

Homestake (1999 to 2001)

Resolute (1994 to 1999)

Battle Mountain Australia Inc. (Pre 1994)

Inco (1969-1971 and 1972-1976)

For Mineral Resource estimation, the Plutonic main underground area has been predominantly based on diamond drilling (DD) from surface and underground platforms and underground rock chip face samples (FS). Reverse Circulation (RC) drilling makes up a small proportion of the data set and has been carried out at the Plutonic main deposit for delineation of open pit material.

Diamond core diameters include BQ (36.4 mm), BTW (42 mm), LTK60 (43.9 mm), NQ (47.6 mm), NQ2 (50.7 mm). RC holes were drilled with face hammers and were sampled at one metre down hole intervals. Face chip samples are completed by the mine geologists. The sampling is taken by chipping the face into calico bags with definition by lithological boundaries.

Underground hole collar locations are picked up regularly by site surveyors. Multi-shot cameras are used for down-hole survey. Face chip samples are spatially positioned within underground development voids which are picked up regularly by site surveyors.

3. Sampling and Subsampling

Exploration DD core is sawn in half along the orientation lines, with half the sample being submitted for assay and the remaining half being retained for reference. Grade control DD core is whole core sampled and sent for analysis. DD core samples were taken at 1 m intervals or at geological boundaries.

RC samples were collected for each metre drilled and passed through a cyclone and riffle splitter to produce a two kg to four kg assay into calico bags.

Rock chip FS are completed by the mine geologists. The sampling is taken by chipping the face into calico bags with definition by lithological boundaries. FS samples are taken perpendicular to the lode orientation in the face. The face sample locations are marked up and measured from fixed survey points.

DD recovery is not noted specifically, though core is locked in, and meter marked carefully. Discrepancies to core blocks are brought up with the drill contractor. Occasionally core loss blocks are inserted. Overall drill core recovery is very high due to the competent nature of the ground.

Rock chip FS recoveries are not relevant in this instance. No RC drilling has taken place at Plutonic for several years and impact on the Mineral Resource would be minimal.

4. Sample Analysis Method

The Plutonic Gold Mine has been in operation since 1990 following discovery in 1988. QAQC procedures have changed throughout that period. The current underground Mineral Resources have been identified over a long period of time with a number of companies. All high confidence Mineral Resources are based dominantly on underground DD and FS completed in the last 14 years.

In recent years, for DD and FS, gold concentration is determined by fire assay using the lead collection technique with a 40gm sample charge weight. An AAS (Plutonic site laboratory) or ICP (ALS and Bureau Veritas) finish. A Pulverising and Leach (PAL) method was introduced to the Plutonic site laboratory in 2005. Underground GC samples are initially assayed by PAL and where the result is greater than 0.5 g/t Au the sample is re-analysed by 40gm fire assay and the fire assay result is retained for grade estimation purposes. It has been shown that the use of PAL assays is likely to have negligible influence on the Mineral Resource.

Sample preparation procedures for DD and FS includes:

1-4 hours drying at 150°C depending on moisture content;

Crush 85% < 3mm – Essa jaw crusher or rotary Boyd crusher;

Riffle split 50:50 to<1kg;

Pulverise ~700-750g to 90% passing 75μm in Labtechnics LM2;

Scoop 250-300g.

Scoop to subset to 40gm for fire assay.

Quality control procedures for DD and FS includes:

FS – blanks added to each face sample with ore zones;

DD –barren wash and blanks added after each ore interval;

Crusher duplicates taken at 1:40;

Pulp duplicates taken at 1:40.

Sample preparation protocols and sample sizes are considered appropriate for the style of mineralisation encountered and should provide representative results.

Certified Reference Material (CRM's) are submitted every 20 samples for DD and once per shift for FS (approx. 1 in 15 samples). CRM's are of similar grade tenor to those expected in the sampling. The CRM insertion rate ensures that there are at least two CRM's per assay batch. CRM's are selected based on their grade range and mineralogical properties with an emphasis on sulphide ores.

Blanks are inserted every 20 samples for DD and for FS they are inserted after any face that contains mineralisation.

Conclusions from the MRE Competent Person include:

Results indicate that the QAQC performance is sufficient for using the data for an underground Mineral Resource Estimate;

Element of risk in using PAL due to incomplete digestion;

Site laboratory performance (the majority of the samples) is poorer than off-site commercial laboratories (ALS and Bureau Veritas) due to contamination and percentage of CRM failure;

Site laboratory shows poorer performance at low levels of Au (0.4 - 0.8 g/t), but effect on underground Mineral Resources likely to be minimal;

Precision of CRMs for site laboratory poorer than manufacturer.

5. Resource Estimation Methodology

Plutonic gold mineralisation is almost entirely hosted within the Mine Mafic Unit (MMA) and characterised by a significant population of high to extreme gold grades that demonstrate very poor spatial continuity (only a few meters at best). Raw Coefficients of Variation (CoV) are typically in the order of 15-30, indicating extreme statistical variability.

The estimation method developed for the MRE combines Categorical Indicator Kriging (CIK) to define broad estimation domains, together with applying distance limiting at chosen grade thresholds to restrict the influence of the high grade and extreme grade values during grade interpolation.

Prior to estimation, a closely spaced set of structural surfaces are developed in LeapFrog reflecting the primary controls on mineralisation within the MMA. A dip and dip-direction of each triangle facets is imported into the Surpac block model to provide information for dynamic search and variogram model orientation during grade interpolation. Dynamic estimation is applied for estimating the CIK indicators and gold grades.

All DD and FS data are composited to 1m downhole and data within dolerite dykes or vein zones are removed. Composited data was split into the eight mine areas.

Two Categorical Indicator values are determined for each mine area:

A low-grade (LG) indicator to differentiate between background 'waste' and low-tenor mineralisation – around 0.5 g/t Au.

A high-grade (HG) indicator to define broad areas of consistent higher-tenor mineralisation – typically between 1.1 g/t and 1.7 g/t Au.

Indicator variograms were modelled for the LG and HG thresholds for all mine areas. The indicator variograms for both grade thresholds exhibited a moderate nugget effect and demonstrated well-structured continuity up to 30m. The CIK indicators were estimated using Ordinary Kriging into a finely gridded block model with block dimensions of 1.25m x 1.25m x 1.25m. The small block size for the indicator process is beneficial for creating categorical sub-domains at resolution which can be used to accurately back-flag composite data.

Three categorical sub-domains were generated for low-grade (LG), medium-grade (MG) and high-grade (HG) areas. The HG sub-domain was based on an indicator probability threshold of 0.35 and the LG sub-domain was based on an indicator probability threshold of 0.65. The MG sub-domain is assigned to blocks that do not satisfy either the HG or LG sub-domain criteria.

The three categorical block model sub-domains (HG, MG and LG) were used to 'back-flag' the 1m composites from each mine area, thus creating a separate composite file for each sub-domain.

Standardised assay top-cuts are applied to the composite files as follows:

HG = 300 g/t Au

MG = 40 g/t Au

LG = 20 g/t Au

The assay top-cuts were generally above the 99th percentile of the distribution and were aimed at globally limiting extreme values only. Top-cuts are not used as the primary tool to control metal risk. The use of grade thresholds and distance limiting is considered a more objective and influential method in controlling metal risk, while better reflecting the actual localised occurrence of discontinuous high-grade gold mineralisation.

Grade variograms were modelled for the LG, MG and HG sub-domains for all mine areas. The HG grade variograms exhibited a very high nugget effect (75-82%) with maximum ranges of only a few meters (2.9-3.9m). Grade variography undertaken on the HG domain confirms the extremely variable nature of Plutonic mineralisation. As expected, grade variography on the MG and LG domains resulted in lower nuggets effects and longer ranges. Given the similarities between the spatial characteristics between all mine areas, it was decided to use an average gold grade variogram for each domain across all mine areas.

Grade thresholds for distance limiting were determined for each mine area from log-probability plots. Initial distance limits were determined by undertaking indicator variography at each grade threshold value. Distance limits were subsequently optimised following a detailed backward-looking mill reconciliation using mine stope voids for the period January 2023 to August 2023 (550Kt).

Prior to grade estimation, sub-domain codes from the 1.25m resolution block model are imported into a 2.5m x 2.5m x 2.5m resolution model and the proportion of LG, MG and HG is calculated for each 2.5m block. Grade estimation for the LG, MG and HG domains was undertaken in Surpac software using Ordinary Kriging with grade threshold distance limiting. Search routines and variogram orientations are drawn from the pre-populated dynamic search information recorded in each block.

Final block grades at a 2.5m block resolution were calculated by weighting the estimated grades for each sub-domain by the relevant domain proportion.

The parent estimation block size was 2.5m x 2.5m x 2.5m. A minimum of 3 and maximum of 12 (1 m composite) samples per block were used. Block discretisation was set at 3 E x 3 N x 3 RL points (per parent block).

A standardised search ellipse of 25m x 25m x 6.25m was used. Octant restrictions were not used.

Typical data spacing varied from 3m x 3m to >40m x 40m.

The model was validated by comparing statistics of the estimated blocks against the composited sample data; visual examination of the of the block grades versus assay data in section; swath plots; and reconciliation against previous production.

Bulk density was directly assigned by oxidation type and rock type:

Fresh MMA and Ultramafic = 2.9 t/m3

Transitional MMA and Ultramafic = 2.2 t/m3

Oxide MMA and Ultramafic = 1.8 t/m3

Fresh Quartz = 2.5 t/m3

Transported/Laterite = 2.1 t/m3

Pit Backfill and Surface Dumps = 1.8 t/m3

Mining depletion to June 30th 2023 was applied to the model. Mining depletion is represented as a 'void proportion' at a 2.5m block resolution.

6. Classification Criteria

The Mineral Resource has been classified following due consideration of all criteria contained in Section 1, Section 2 and Section 3 of JORC 2012 Table 1.

The supplied drilling database represents an appropriate record of the drilling and sampling undertaken at the project. In general drilling, surveying, sampling, analytical methods and controls are considered appropriate for the style of mineralisation under consideration.

The continuity and volume of the mineralised domains has been established by surface and underground diamond drilling, together with extensive underground development and production history.

The estimation method and the associated search and interpolation parameters used are considered appropriate for estimation of the Mineral Resources and have been calibrated to recent production reconciliation.

Cube has considered all the relevant criteria and has classified the estimated Mineral Resources as Indicated and Inferred Mineral Resource.

The portions of the MRE classified as Indicated are typically based on drill spacing less than or equal to 30 m x 30 m. This drill spacing is appropriate for defining the continuity and volume of the mineralised domains and estimating robust global Mineral Resources. Approximately 85% of the Indicated portion of the MRE has been drilled at closer then 30 m x 30 m and 70% of the Indicated portion has been drilled at better than 24 m x 24 m.

The portions of the MRE classified as Inferred typically represent peripheral areas of the deposit where geological continuity is present but not consistently confirmed by 30 m x 30 m drilling or closer.

Further considerations of resource classification include; data type and quality, geological understanding, amount of historical development and stoping, and historical and recent production reconciliation performance.

The Mineral Resource classification appropriately reflects the view of the Competent Person.

7. Reasonable Prospects for Eventual Economic Extraction

The Plutonic Gold Mine has operated continuously for 33 years. The Mineral Resource is considered to have reasonable prospects for eventual economic extraction (RPEEE) given the access to critical infrastructure, the volume and grade of mineralisation available for mining and the RPEEE criteria which have been applied prior to reporting the Mineral Resource.

Reporting Cut-off Grades

The Plutonic underground Mineral Resources are reported at a cut-off grade of 1.5 g/t Au. The cut-off grade has been derived from current mining and processing costs and metallurgical parameters. Inputs into the cut-off grade calculation include:

Incremental Stoping and Grade Control Cost = AUD$60/t

Processing Costs = AUD$31/t ore

Site Administration Cost = AUD$23/t ore

Metallurgical Recovery = 84%

Royalties = 2.5%

Gold Price = AUD$2,800/oz

In addition to applying a cut-off grade of 1.5 g/t Au, the Mineral Resource has been reported within an underground Shape Optimiser (SO) evaluation from the undiluted and depleted resource model. SO input parameters include a minimum mining width of 3m, minimum stope length of 5m, stope height of 15m.

8. Mining and Metallurgical Methods and Parameters

Plutonic is an operating mine and there are no material metallurgical issues that are known to exist.

MINERAL RESOURCE ESTIMATE (Trident)

Cube Consulting Pty Ltd (Cube) was commissioned by Catalyst to prepare a Mineral Resource estimate (MRE) for the Trident Gold Deposit (the Project), located in Western Australia.

Cube considered that data collection techniques are largely consistent with industry good practice and suitable for use in the preparation of a MRE to be reported in accordance with the JORC Code. Available quality control (QC) data supports use of the input data.

The Trident deposit comprises fourteen mineralised domains that have been estimated into a single block model based on all available data at 5th September 2023.

A three-dimensional (3D) block model representing the mineralisation was created using Leapfrog and Surpac software. Surface Diamond Drilling (DD) core and Reverse Circulation (RC) chips were used to interpolate gold grades into blocks using Ordinary Kriging. The block model was validated by visual checks, statistical comparisons, and swath plots to ensure that the block model was a good representation of the drillhole composite data.

The Mineral Resource is considered to have reasonable prospects for eventual economic extraction (RPEEE) given the access to critical infrastructure, the volume and grade of mineralisation available for mining and the RPEEE criteria which have been applied prior to reporting the Mineral Resource.

On Figure 1, the Trident Mineral Resources are presented in an isometric projection.

The following is a material information summary relating to the MRE, consistent with ASX Listing Rule 5.8.1 requirements. Further details are provided in JORC Table 1, which is included as Appendix A.

1. Geology and Geological Interpretation

The Trident gold deposit is located within the Archaean Plutonic Well Greenstone Belt, an elongate NE trending belt within the Marymia Inlier. The Marymia Inlier is an Archaean basement remnant within the Proterozoic Capricorn Orogen, and comprises two mineralised greenstone belts (Plutonic Well and Baumgarten greenstone belts), with surrounding granite and gneissic complexes. The Capricorn Orogen is situated between the Pilbara and Yilgarn cratons and is interpreted to be the result of the oblique collision of these two Archaean cratons in the early Proterozoic.

It is a structurally controlled, orogenic, mesothermal (amphibolite metamorphic facies) gold deposit hosted by ultramafic rocks that are part of strike extensions to the Plutonic Gold Mine stratigraphy. The gold deposit is specifically hosted by shallow to moderate dipping, ultramafic tremolite – phlogopite (mica) schist, immediately overlying serpentinised ultramafic units, derived from higher MgO ultramafic volcanics.

High-grade gold zones are best developed within the shallow dipping ultramafic tremolite – phlogopite schist where it is bent into a concave flexure, in the hanging wall of steep, north-westerly dipping fault structures. Vertical "dragging" movement against these steeply dipping faults appears to have played a role in dilating the cleavage of the ultramafic schist, resulting in mineralisation and alteration between the dilated cleavage planes. The steeply dipping faults also host gold mineralisation.

Gold mineralisation is associated with potassic, phlogopite mica alteration and has a low proportion of quartz and sulphides, including minor pyrrhotite, pentlandite, chalcopyrite and, directly associated with gold, bismuthinite and rare bismuth tellurides. Rarely observed gold grains (in microscopy) are predominantly fine (<50 micron) but free and/or attached to, and rarely occluded within, sulphide grains.

2. Drilling Techniques

The sampling database for Trident includes data collected by diamond drilling (DD) and Reverse Circulation (RC) techniques. The sampling database has been compiled from information collected when the Project was under ownership of numerous companies including (listed from most recent):

Catalyst Metals (2022 to current)

Vango (2013 to 2023)

Dampier Gold (2012 to 2013)

Barrick Gold (2001 to 2012)

Homestake (1999 to 2001)

Resolute (1994 to 1999).

Battle Mountain Australia Inc. (Pre 1994)

Inco (1969-1971 and 1972-1976)

For the most recent drilling completed by Catalyst and Vango, planned drill hole collars were pegged with a DGPS and marked with wooden pegs hammered into the ground and flagged with high visibility flagging tape.

On completion of drilling, the actual drill hole collar position is measured by survey staff using a DGPS working off a network control of survey stations, to an accuracy of 20 mm from the nearest survey station. These coordinates replace the planned coordinates in the geological database. These collar co-ordinates are then uploaded to the database, where a transformation is performed on them, where the holes are rotated to populate the local grid co-ordinates (Trident Local Grid).

The survey station network meets the Mine Safety and Inspection Regulations 1995, section 3.49, where the accuracy of a survey must be not less than 1:5000.

The collar locations of historic drill holes were validated from geological logging information from annual reports and the original database when Vango acquired the tenure.

The majority of drill holes used in the resource estimate have been accurately surveyed by qualified surveyors using DGPS. Downhole surveys have been conducted at regular intervals using industry-standard equipment.

Some magnetic units have affected the azimuth readings where single shot cameras were used and these records have not been used. Many holes have been surveyed using Gyro tools.

All Vango/Catalyst holes used in the resource estimate have some form of down hole survey. Recent (2023) downhole survey data was collected by Westdrill using an Axis Mining Technology Champ North Seeking Gyro tool. Surveys are conducted at EOH using a north seeking gyroscope reading every 5 m. If early drilling finds strong hole deviation, then surveys are conducted during drilling (collar, 30 m, 60 m, 90 m etc to EOH). Survey deviation is supervised by the geologist onsite, with major deviation discussed with the driller at the time.

Previous downhole survey data was collected using a REFLEX gyro tool and historically with Eastman cameras, with follow-up downhole surveys carried out by Surtron using gyroscopic survey equipment. Historical downhole surveys were reviewed and verified where information was available through direct comparison within the database.

3. Sampling and Subsampling

Diamond drilling assays are from mostly half core and minor quarter core, NQ2 and HQ size core. This is considered to be sufficient material for a representative sample. Core samples were taken at 1 m intervals or at geological boundaries.

RC drilling assays are from 1 m samples split on the cyclone for the ultramafics. 4 m composites from these 1 m splits are taken in the cover sequence. Historical RC samples were collected as 4 m composite spear samples. Mineralised zones were sampled at 1 m intervals using a 1/8 riffle splitter.

Recovery in diamond drilling is based on measured core returned for each 3 m. RC drilling was bagged on 1 m intervals and an estimate of sample recovery has been made based on the size of each sample.

No assessment of RC chip sample recoveries was undertaken on historical data however a comprehensive historical review of sampling procedures was undertaken which indicates that standard procedures where enacted to ensure minimal sample loss. Where information on the recoveries has been recorded, they have been consistent with those noted by recent drilling.

4. Sample Analysis Method

Information sourced indicates that several analytical laboratories have been used over the history of the Trident Deposit, and analytical methodologies have varied slightly over time. Typically fire assay with determination by atomic absorption spectrometry (AAS) has been used. Where records have been found the assay protocols were as follows:

1995: 230 RC pre-collar and 1473 core sample submitted to Minlab, Malaga for Au Fire Assay.

1996: Minlab, Malaga for Au Fire Assay.

1997: Minilab, Malaga RC - Aqua Regia check samples and standards, DD - Fire Assays.

1998: Minilab, Malaga RC - Aqua Regia check samples and standards, DD - Fire Assays.

2002: Samples were assayed for gold and arsenic at Amdel Laboratory (Perth); gold analysis was carried out using a 50 g charge fire assay with AAS finish (detection limit of 0.01 ppm).

2007 to 2010: Assay sample preparation comprised the crushing of RC chips and half-core, splitting and pulverising 500 - 800 grams to 90% passing 106 µm at the Plutonic Gold Mine laboratory. A representative 30 gram charge was assayed for Au by Aqua Regia with Atomic Adsorption Spectrometer grade determination. The lower detection cut-off limit was 0.01 ppm. All samples reporting greater than 0.3 g/t and other selected samples were then forwarded to Amdel Laboratories for analysis by fire assay, using a 40 gram charge. Five percent of samples sent to Amdel were forwarded to Genalysis for further check fire assaying. Five percent of all RC samples were submitted to the PGM laboratory for check sample preparation and assaying.

2012: Drill chip samples were dispatched to the Genalysis Laboratory in Perth for analytical work. The chips were subject to a SSMG grind time of four minutes and the resultant pulp was assayed to Genalysis's Fire Assay Standard FA25 AAS, RC and diamond FA25 SAA and RAB were assayed for multi elements.

Recent samples were analysed at ALS Malaga using a 50 g Fire Assay method. Samples were dried, crushed and pulverised prior to analysis.

Although sample collection, sample preparation, sample logging and analytical techniques have varied over the Project's history, all can be considered as industry standard at the time. The amount of QC data that was collected has also varied over the Project's history, but overall is considered as being acceptable to support the MRE.

Details relating to drilling techniques, quality assurance (QA) protocols and quality control (QC) results for data gathered prior to 2013 was documented and validated through an extensive WAMEX review. 1,266 historical Standards were analysed with the results showing no major issues. Overall historical blank performance was considered acceptable, with no evidence of contamination observable in the results. 100% of samples were within the pass limit (5x the detection limit)

For recent drilling, a technical summary that outlined the independent performance analysis of the (QAQC) samples routinely inserted as part of the RC and DD operations at the Trident Gold Deposit was undertaken by Cube Consulting in August 2023. 2,334 QC materials were analysed, with no issues discovered.

5. Resource Estimation Methodology

All geological domains used in the MRE were constructed by Cube using Leapfrog software. Block modelling and grade interpolation were carried out by Cube Consulting using Surpac software. Statistical analysis was carried out by Cube Consulting using Snowden Supervisor software.

All drillhole assay samples were flagged according to the geological and mineralisation envelopes. Sample populations were statistically analysed, and estimation domains defined. Assay top cuts were applied to 1 m composites prior to grade interpolation.

Quantitative kriging neighbourhood analysis was undertaken to assess the effect of changing key kriging neighbourhood parameters on block grade estimates. Kriging efficiency and slope of regression were determined for a range of block sizes, minimum/maximum samples, search dimensions and discretisation grids.

Within each domain, an Ordinary Kriging (OK) or Invese Distance Squared (ID²) estimate of gold grade was produced using the cut composite data. The ellipsoid search parameters were based on the variogram ranges, with the search ellipse dimensions similar to the variogram range, with anisotropies retained. Due to the orientation of some of the drill holes in relation to the mineralisation a maximum number of samples per drill hole was applied to a number of lodes. Hard boundaries were used for the estimate.

A minimum of 8 and maximum of 16 (1 m composite) samples per block were used for the estimation, with the minimums and maximums established through independent KNA on each major domain. Block discretisation was set at 5 E x 5 N x 3 RL points (per parent block).

Octant restrictions were not used, and estimates were into parent blocks, not sub-blocks.

Lodes estimated by OK used search ellipse rotation directions as determined by dynamic surfaces.

Subsequent search passes were applied to domains when blocks did not estimate at the first pass.

When appropriate, dynamic anisotropy was employed to ensure undulation in the mineralisation relating to the folded nature of the stratigraphy was captured by the search ellipses (i.e. rotating search ellipses).

Estimating using OK in domains with a mixed sample population can result in the higher-grade samples having a greater spatial influence than is warranted. As such, distance limiting of grades above a threshold over a certain distance was used. This resulted in the higher grades being more locally representative and not having an influence over distance.

After assay top-cutting, probability plots were reviewed to look for points of inflection in the sample data. This was used as an indicator of where the distance limiting function was applied.

Model validation was completed to check that the grade estimates within the model were an appropriate reflection of the underlying composite sample data, and to confirm that the interpolation parameters were applied as intended. Checks of the estimated block grade with the corresponding composite dataset were completed using several approaches involving both numerical and spatial aspects as follows:

Globally: Comparison of the mean block grade estimates to the mean of informing composite grades for both domain

Semi-Local: Using swath plots in Northing and RL comparing the estimates to the sample data

Local: Visual inspection of the estimated block grades viewed in conjunction with the sample data.

Density has been assigned to the resource using interpreted weathering surfaces determined from drill hole logging. Bulk density was coded by oxidation type:

Oxide = 1.8 t/m3

Transitional = 2.4 t/m3

Fresh = 2.9 t/m3

Over 200 density measurements were available for review predominantly in fresh material. Data was imported into Leapfrog software and statistics were compared for mineralised zones/waste and different lithologies.

With limited data available for oxide and transitional domains the density values have been defaulted to what had been coded previously and what was used in the nearby Marwest Pit.

6. Classification Criteria

The Mineral Resource has been classified following due consideration of all criteria contained in Section 1, Section 2 and Section 3 of JORC 2012 Table 1.

The supplied drilling database represents an appropriate record of the drilling and sampling undertaken at the project. In general drilling, surveying, sampling, analytical methods and controls are considered appropriate for the style of mineralisation under consideration.

The drill spacing is relatively consistent within the mineralised domains at nominal 20 m drill spacing on 20 m sections with some 40m and 80 m drill spacing on sections in the deeper edge margins of the deposit.

The recent drilling has generally confirmed the previously classified Indicated material.

Drill holes are routinely surveyed for down hole deviation using appropriate methodology. Given the dimensions and general attitude of the modelled mineralisation, down hole deviation is considered a low risk of materially impacting the MRE.

The continuity and volume of the mineralised domains has been established by diamond and RC drilling to a confidence level where the grade and quantity can be reasonably assumed. The approach to defining the mineralised volume was firstly based on geological attributes, modified by applying a geological cut-off grade for each mineralised wireframe.

In general, the interpreted mineralised volumes have been extrapolated generally half the drill hole spacing beyond data limits.

The OK and ID² modelling method and the associated search and interpolation parameters used are considered appropriate for estimation of the Mineral Resources at this stage of the project evaluation. Cube have concluded the OK and ID² grade outcome is the appropriate model to report for the October 2023 MRE. The estimate has also been compared to previous estimates.

Cube has considered all the relevant criteria and has classified the estimated Mineral Resources as Indicated and Inferred Mineral Resource.

The portions of the 2023 MRE classified as Indicated have been flagged by medium to high quality estimation parameters, an average distance to nearest sample of 25 m. The drill spacing within the Indicated portion of the resource is appropriate for defining the continuity and volume of the mineralised domains, at a nominal 20 m drill spacing on 20 m sections.

The portions of the 2023 MRE classified as Inferred represent typically minor lodes with less than three drill holes and portions of domains where geological continuity is present but not consistently confirmed by 20 m x 20 m drilling. The Inferred portions of the MRE are defined by a lower quality of estimation parameters, an average slope of regression (true to estimated block) of < 0.3 and an average distance to composites used of > 30 m.

7. Reasonable Prospects for Eventual Economic Extraction

The Mineral Resource is considered to have reasonable prospects for eventual economic extraction (RPEEE) given the access to nearby critical infrastructure, the volume and grade of mineralisation available for mining and the RPEEE criteria which have been applied prior to reporting the Mineral Resource.

8. Reporting Cut-off Grades

The Trident MRE is reported at a cut-off grade of 1.5 g/t Au. The cut-off grade has been derived from a first principals build-up of mining and processing costs and metallurgical parameters as part of the ongoing DFS. Inputs into the cut-off grade calculation include:

Stoping, Grade Control and Surface Haulage Cost = AUD$73.59/t ore

Processing Costs = AUD$31/t ore

Site Administration Cost = AUD$5.58/t ore

Metallurgical Recovery = 83.5%

Royalties = 2.5%

Gold Price = AUD$2,800/oz

In addition to applying a cut-off grade of 1.5 g/t Au, the MRE has been reported within an underground Shape Optimiser (SO) evaluation from the undiluted resource model. SO input parameters include a minimum mining width of 2m, minimum stope length of 2.5m, sublevel spacing of 5m.

9. Mining and Metallurgical Methods and Parameters

Mining of Trident is assumed to be by underground mining methods. Trident ore is assumed to be transported and processed at the Plutonic processing facility. It is assumed that Trident will be an incremental ore source to a base load being processed at Plutonic. The Plutonic plant is an established operation, historical operating costs are generally well understood and reliable. Metallurgical testwork, commissioned by Como Engineers and conducted by ALS Metallurgy, showed that the Trident fresh ore is suitable for treatment via a typical crush, grind and leach process, with final gold recoveries of up to 90%.

Section 1 Sampling Techniques and Data

Plutonic Underground Deposit

(Criteria in this section apply to all succeeding sections.)

Criteria | Commentary |

Sampling |

|

Drilling |

|

Drill sample |

|

Logging |

|

Sub-sampling |

|

Quality of assay |

At the Plutonic Laboratory there was:

At ALS Laboratory there was:

|

Verification of |

|

Location of data |

|

Data spacing |

|

Orientation of |

|

Sample security |

|

Audits or reviews |

|

Section 2 Reporting of Exploration Results

Plutonic Underground Deposit

(Criteria listed in the preceding section also apply to this section.)

Criteria | Commentary |

Mineral |

|

Exploration done |

|

Geology |

|

Drill hole |

|

Data |

|

Relationship |

|

Diagrams |

|

Balanced reporting |

|

Other |

|

|

|

Section 3 Estimation and Reporting of Mineral Resources

Plutonic Underground Deposit

(Criteria listed in section 1, and where relevant in section 2, also apply to this section.)

Criteria | Commentary |

Database integrity |

Surface and underground drill hole and face data is validated to produce a digital database free of detected errors. This is undertaken by passing data through embedded macros and queries of the drill hole database software by table (collar, assay, lithology, survey, and grout). Crosschecks are also undertaken to ensure that each drill hole has data from collar, assays, lithology, survey, and grout files. By undertaking the above procedures, all drill hole and face data is rigorously checked, verified, and corrected where necessary to ensure limited failures.

|

Site visits |

|

Geological interpretation |

|

Dimensions |

|

Estimation and modelling techniques |

|

Area | Threshold 1 | Initial | Final | Threshold 2 | Final |

A134 | 5 | 7 | 10 | 100 | 4 |

Baltic | 10 | 8 | 10 | 100 | 5 |

Caribbean | 7 | 7.5 | 10 | 90 | 6 |

Caspian | 7 | 7 | 10 | 50 | 5 |

Cortez | 8 | 7 | 10 | 40 | 4 |

Indian | 7 | 4.5 | 10 | 50 | 4 |

Pacific | 10 | 11 | 10 | 30 | 8.7 |

Timor | 10 | 9 | 10 | 100 | 6.25 |

Grade Thresholds and Distance Limits | |||||

Criteria | Commentary |

Moisture |

|

Cut-off parameters |

Incremental Stoping and Grade Control Cost = AUD$60/t Processing Costs = AUD$31/t ore Site Administration Cost = AUD$23/t ore Metallurgical Recovery = 84% Royalties = 2.5% Gold Price = AUD$2,800/oz |

Mining factors or assumptions |

|

Metallurgical factors or assumptions |

|

Environmental factors or assumptions |

|

Bulk density |

MMA/Mafic/Ultramafic/Dolerite Fresh = 2.9 t/m3 Transitional = 2.2 t/m3 Oxide = 1.8 t/m3 Fresh Quartz = 2.5 t/m3 Transported/Laterite = 2.1 t/m3 Pit Backfill and Surface Dumps = 1.8 t/m3 |

Classification |

|

Audits or reviews |

|

Discussion of relative accuracy/ confidence |

|

Section 4 Estimation and Reporting of Ore Reserves

Plutonic Underground Deposit

(Criteria listed in section 1, and where relevant in sections 2 and 3, also apply to this section.)

Criteria | Commentary |

Mineral Resource estimate for conversion to Ore Reserves |

|

Site visits | The Competent person is a full-time employee who has visited the site on a regular basis for the past 12 months, and has detailed knowledge of the mining methods, costs, schedule and other material parameters relating to the Ore Reserves estimate. |

Study status |

|

Cut-off parameters |

|

|

|

Metallurgical factors or assumptions | The Plutonic Gold Mine has been in operation since 1990. The original process plant ("PP1") consisted of an open circuit jaw crusher, coarse ore stockpile, semi-autogenous grinding ("SAG") mill and ball mills, two leach tanks, and six carbon adsorption tanks. A three-stage hard rock crushing circuit was incorporated in 1994 which included a fine ore bin and an additional ball mill. A second process plant ("PP2") was added in 1996 utilising the original PP1 jaw crusher and coarse ore stockpile and adding SAG and ball mills, two additional leach tanks and six additional carbon adsorption tanks. A 16 MW gas power station was added in 1997 and upgraded with new sets in 2014 and 2020 respectively. PP1 was designed for the treatment of primary ore while PP2 was designed to process oxide ore. At the end of June 2004, oxide ore sources were exhausted and the crushing and milling components of PP2 were shutdown. However, the leach and carbon adsorption circuit of PP2 was run in parallel with the PP1 leach/adsorption circuit. In April 2008 the PP2 leach and carbon adsorption circuit was emptied, cleaned, and placed into care and maintenance as part of a strategy to reduce the site power load and power consumption due to power restrictions caused by the June 2008 gas supply crisis. The four tanks in the PP2 leach and carbon adsorption circuit that were re-commissioned in June 2010 were shut down in 2012.

The primary sections of the processing plant that are currently in use are:

Plant performance for the past five years indicates reasonable performance, with recoveries ranging from 76% to 90%, and an average recovery in 2023 of 85%. Metallurgical recoveries used to generate the Mineral Reserves were based on site production data and detailed metallurgical testing to an appropriate standard. A summary of the metallurgical recoveries used to determine the cut-off grades is shown in Table 2

|

Mining Area | Met. Recovery |

A134 | 88.80 % |

Baltic | 94.00 % |

Caspian | 81.90 % |

Cortez | 88.80 % |

Indian | 83.10 % |

Pacific | 79.30 % |

Plutonic East | 84.20 % |

Timor | 93.50 % |

Criteria | Commentary |

Environmental | Plutonic maintains a register of legal and regulatory requirements which is updated regularly. The register captures the requirements of relevant environmental legislation.

Construction of the Plutonic Gold Mine site commenced following the submission of a Notice of Intent ("NoI") in 1989 to the Department of Mines and Petroleum ("DMP"), which is now the Department of Mines, Industry Regulation and Safety ("DMIRS"). DMIRS administers and regulates the activities of the mining industry under the provisions of the Mining Act. NoI documents, now known as mining proposal(s) ("MP"), detail the environmental impacts associated with the Project and provide a list of environmental commitments made to manage those impacts in a responsible manner. DMIRS assesses, approves, and manages MP applications, including the associated mine closure plan ("MCP") requirements. There have been several MPs that have been approved to date. The key Plutonic MPs that have been granted for Superior are:

The Department of Water and Environmental Regulation (the "DWER") licenses water abstraction and pollution discharge activities. Plutonic operates in accordance with Part V of the Western Australian Environmental Protection Act 1986 (the "EP Act") under Operating Licence L6868/1989/12, first issued by the DWER predecessor, the Department of Environment Regulation (the "DER") in September 2014. Plutonic has obtained and maintained requirements under Operating Licence L6868/1989/12 for the following prescribed premises to date:

A Native Vegetation Clearing Permit ("NVCP") under Part V of the EP Act and the Environmental Protection (Clearing of Native Vegetation) Regulations 2004 is required to be obtained prior to the commencement of any native vegetation clearing, together with a MP approval from DMIRS. The Project has obtained a number of historic clearing permits to date. The current and most relevant approved NVCPs are:

The abstraction of groundwater for water supply and/or mine dewatering purposes requires licences to be issued by the DWER (Water Section) under section 5C of the Rights in Water and Irrigation Act 1914 (the "RIWI Act"). Plutonic conducts dewatering from open pits and underground, and abstracts production and potable water from Borefields 1 and 2 which are located 30 km and 15 km west of the Plutonic plant. The Project has obtained water licences under the RIWI Act as follows:

Activities undertaken onsite are required to be undertaken in accordance with the above environmental approvals. Monitoring programs are conducted to ensure that key approval and licence requirements are complied with.

|

Infrastructure | The Plutonic Gold Mine is a well-established mine which has services and infrastructure consistent with an isolated area operating mine. The existing site infrastructure is capable of supporting the mine plans as historically the site has successfully operated at production rates significantly higher than those envisaged |

Costs |

|

Revenue factors | The Ore Reserves estimation utilises the current operational costs with an estimated Gold Price of $A2,600/oz. |

Market assessment | Gold metal is a freely and widely traded commodity with a transparent mechanism for setting prices and for sale of gold produced. Catalyst has not conducted any studies or analyses such as commodity price projections, product valuations, market entry strategies, or product specification requirements. |

Economic |

|

Social |

|

Other |

|

Classification |

|

Audits or reviews |

|

Discussion of relative accuracy/ confidence |

|

Section 1 Sampling Techniques and Data

Trident Deposit

(Criteria in this section apply to all succeeding sections.)

Criteria | Commentary |

Sampling techniques |

|

Drilling techniques |

|

Drill sample recovery |

|

Logging |

|

Sub-sampling techniques and sample preparation |

|

Quality of assay data and laboratory tests |

|

Verification of sampling and assaying |

|

Location of data points |

|

Data spacing and distribution |

|

Orientation of data in relation to geological structure |

|

Sample security |

|

Audits or reviews |

|

Section 2 Reporting of Exploration Results

Trident Deposit

(Criteria listed in the preceding section also apply to this section.)

Criteria | Commentary |

Mineral tenement and land tenure status |

|

Exploration done by other parties |

|

Geology |

|

Drill hole Information | Vango Work

Historical Work

|

Data aggregation methods |

|

Relationship between mineralisation |

|

Diagrams |

|

Balanced reporting |

|

Other substantive exploration data |

|

Further work |

|

Section 3 Estimation and Reporting of Mineral Resources

Trident Deposit

(Criteria listed in section 1, and where relevant in section 2, also apply to this section.)

Criteria | Commentary |

Database integrity |

|

Site visits |

|

Geological interpretation |

|

Dimensions |

|

Estimation and modelling techniques |

|

Moisture |

|

Cut-off parameters |

|

Mining factors or assumptions |

|

Metallurgical factors or assumptions |

|

Environmental factors or assumptions |

|

Bulk density |

|

Classification |

|

Audits or reviews |

|

Discussion of relative accuracy/ confidence |

|

View original content to download multimedia:https://www.prnewswire.com/news-releases/plutonic-and-trident-mineral-resource--ore-reserve-update-302007825.html

SOURCE Catalyst Metals LTD.